Machine Room Accessories

Machine Room Accessories

EECO provides Machine Room Accessories for all of our Elevator Control Valves and Power Units.

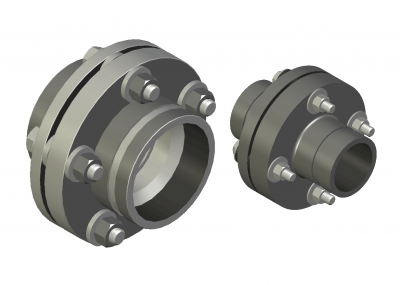

The Isolation Couplings (ISO) are available in three sizes both grooved and threaded. These couplings are designed for electrical isolation with a Dielectric Strength of 42 kV and will also help in the reduction of vibration and noise from being transmitted to the cab. The maximum operating temperature for these Isolation Couplings is 225º F (107º C).

All Isolation Couplings are designed to meet or exceed ASME A17.1/CSA B44.

The Shut Off Valve (SOV) is used to isolate one section of the system from another. All Shut Off Valves are constructed of ductile iron bodies and use a stainless steel ball. A locking device is standard on all sizes.

(includes Ball Valve & Handles}

The Muffler (MU) provides superior noise suppression for most standard

power unit installations. The unit working pressure is 1200 psi and it is 11-3/4” long.

Unit diameter for 2” size is 6-5/8” and 8-5/8” for other sizes.

The EECO Hydraulic Dampener (EHDN) is extremely effective in suppressing the sound and pulsation present in hydraulic elevator systems. The EHDN has a minimum burst pressure of 6000 psi with an ASME A17.1/CSA B44 allowable working pressure of 1200 psi. Unit diameter is 8-5/8” and the length for 2", 2.5", and 3" is 11.75". The 4" outlet unit has a diameter of 10.75" and a length of 13.75".

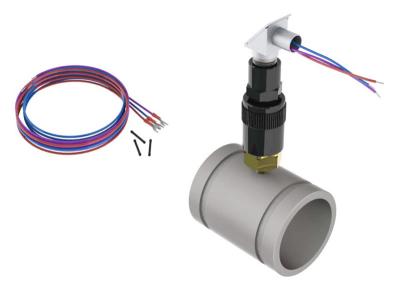

EECO’s Load Weighing Kit (LWK) is an addition to a new or existing Power Unit to prevent the elevator from being overloaded. The switch can be wired into the controller, if the provision is available, through either a normally open or normally closed contact. The kit consists of a field adjustable pressure switch with 48” wire leads, a 4-1/2” long grooved nipple (2”, 2-1/2”, 3”, & 4” sch 80), a 1/2” flex 90° screw-in conduit fitting, and (3) 5’-0” extensions of 18 awg wire with butt splices and #8 spade terminals.

Load Weighing Switch also available separately. Part No. 5719

The Load Weighing Switch is a field adjustable switch. It has a normally open and normally closed contact and is supplied with 48” leads. The switch is mounted by a 1/4" NPT fitting and has a provision to attach a 1/2" conduit.

Specifications:

SPDT, 5 Amp @125/250 VAC Temperature Range: -20° to +165° UL Recognized and CSA Listed Pressure Rated to 7000 psi Adjustable Range ±2%

Decreasing 190 - 450 psi Increasing 250 - 600 psi

The Valve Return Filter (VRF) is a passive oil filtration system attached to the tank return port of the valve. The filtration bag can be easily replaceable without having to remove the bag’s flange. The VRF allows you to easily comply with the ASME A17.1/CSA B44 Rule 8.6.5.1.1 by capturing particles 5 microns in size and larger preventing the buildup of debris within the tank making it easier to clean.

The Valve Return Filter is available with 2" male pipe thread, 2" female pipe thread, or 2" grooved connections. The filtration bag is rated at 200 gpm.

When greater flow rates are required a second VRF needs to be installed in parallel. Filter bags are required to be replaced when the tank return port pressure is 3 – 5 psi or bags become discolored, brown/black in color. The top of the flange is to be located no more than 16-3/4" from the minimum oil level.

The Thermal Switch Assembly is required to be installed on all Hydraulic Power Units, per ASME A17.1/CSA‐B44 3.26.6.5, to prevent the oil temperature from rising above its maximum operating temperature. This assembly can be used in both Submersible and Dry Power Units.

The switch is factory pre‐set at a temperature setting of 145º F (63º C) and will fit in a tank up to 44" tall. Conduit length is 19" and can be trimmed if necessary for a shorter tank. For more information on the electrical characteristic of the switch see Sales Bulletin SB‐026.

A thermostat that is field adjustable by a fine adjustment trim screw which can activate a viscosity

control system. The thrermostat is UL and CSA recognized for a maximum of 1500 watts at 230 volts AC

with a single contact. The unit has a heat sensitive base plate which can be mounted directly to the

outside of a hydraulic tank or by an aluminum “L” bracket with little loss of sensitivity.

This switch can be used to control pump/motor running in bypass mode to heat up the oil in lieu of

a tank heater or as a control to turn on/off an oil cooler and/or a tank heater. The switch is normally

closed and is open above the set temperature.

Specifications:

Range: Adjustable from 75ºF (off) to 525ºF

Rotation: 310 Angular Degrees

Terminal Connector: #6-32 Screw